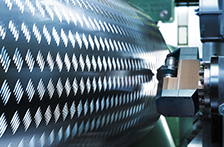

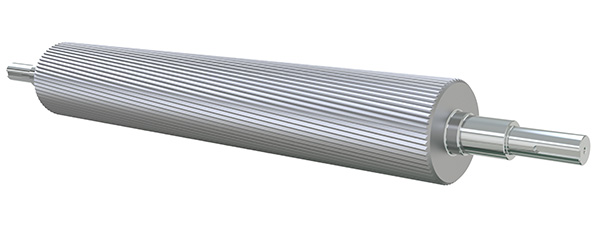

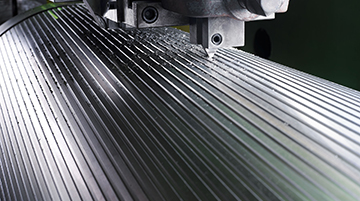

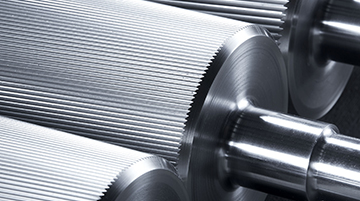

Technical data

Inquire now

| Industry |

flour milling, animal feed production, oil seed industry |

| Common diameter |

150 – 400 mm |

| Common roll body length |

100 – 2,500 mm |

| Material |

static casting TR 100 – TR 120, |

| Design |

hollow, |

| Journals |

made from steel – shrunk in |

| Surface |

axial or radial fluted, |

| Special features |

blanks available |

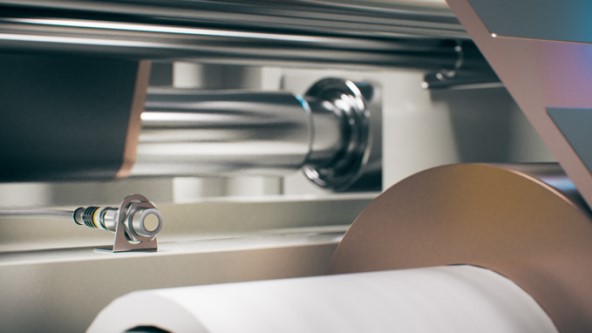

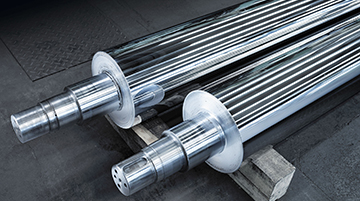

Technical data

Inquire now

| Industry |

flour milling, animal feed production |

| Common diameter |

150 – 400 mm |

| Common roll body length |

100 – 2,500 mm |

| Material |

static casting TB 100 – TB 120, |

| Design |

hollow, |

| Journals |

made from steel – shrunk in |

| Surface |

cylindrically ground or ground with crown, shot blasted |

| Special features |

blanks available |