Production optimization and uniform flake density

"The more robust the flaking roll and with less maintenance necessary,

the better its flaking properties."

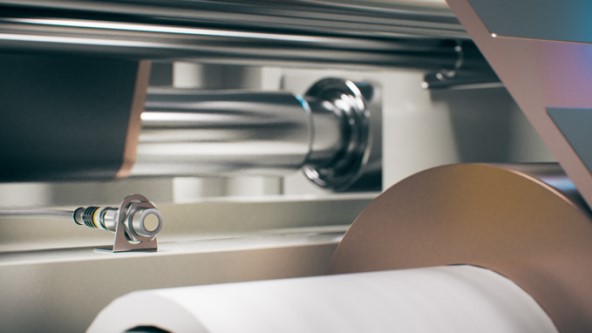

Specialized in the requirements of oilseed processing and always at the cutting edge thanks to ongoing research: The self-surfacing flaking rollers for oil milling are used worldwide for the reliable, efficient processing of seeds and contribute significantly to the optimum product quality of our customers.

The self-surfacing flaking rollers are low-maintenance, durable and impress with their optimum properties, including

-

No edge or shell flaking (with appropriate maintenance)

-

No pitting or wrapping

-

Uniform flake density

-

Consistent wear behavior compared to conventional roller material

-

Absolutely smooth running due to optimized machining

-

Excellent feed performance (the appropriate surface roughness is created by the self-surfacing effect of the material)

Thanks to the technical advantages of the rollers and our comprehensive BREITENBACH service, you can significantly improve your production figures in oilseed processing while relying on our experience and quality standards. The uniform flake density leads to improved extraction, while the low-abrasion flaking rollers offer extended maintenance intervals and thus longer trouble-free operating times.

And as with all BREITENBACH products, this also applies here: MADE IN GERMANY - according to your wishes.

| Industry |

oil seed industry, animal feed production und production of cornflakes and oat flakes (cereals) |

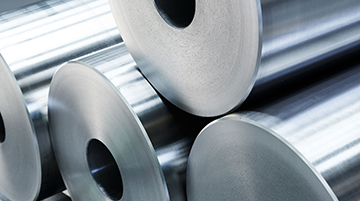

| Common diameter |

400 – 1,000 mm |

| Common roll body length |

600 – 2,500 mm |

| Material |

static casting TR 100 – TR 120, |

| Design |

solid, with centre bore, |

| Journals |

made from steel – shrunk in, |

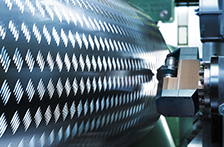

| Surface |

cylindrically ground or ground with crown, fluted |

| Special features |

blanks available |